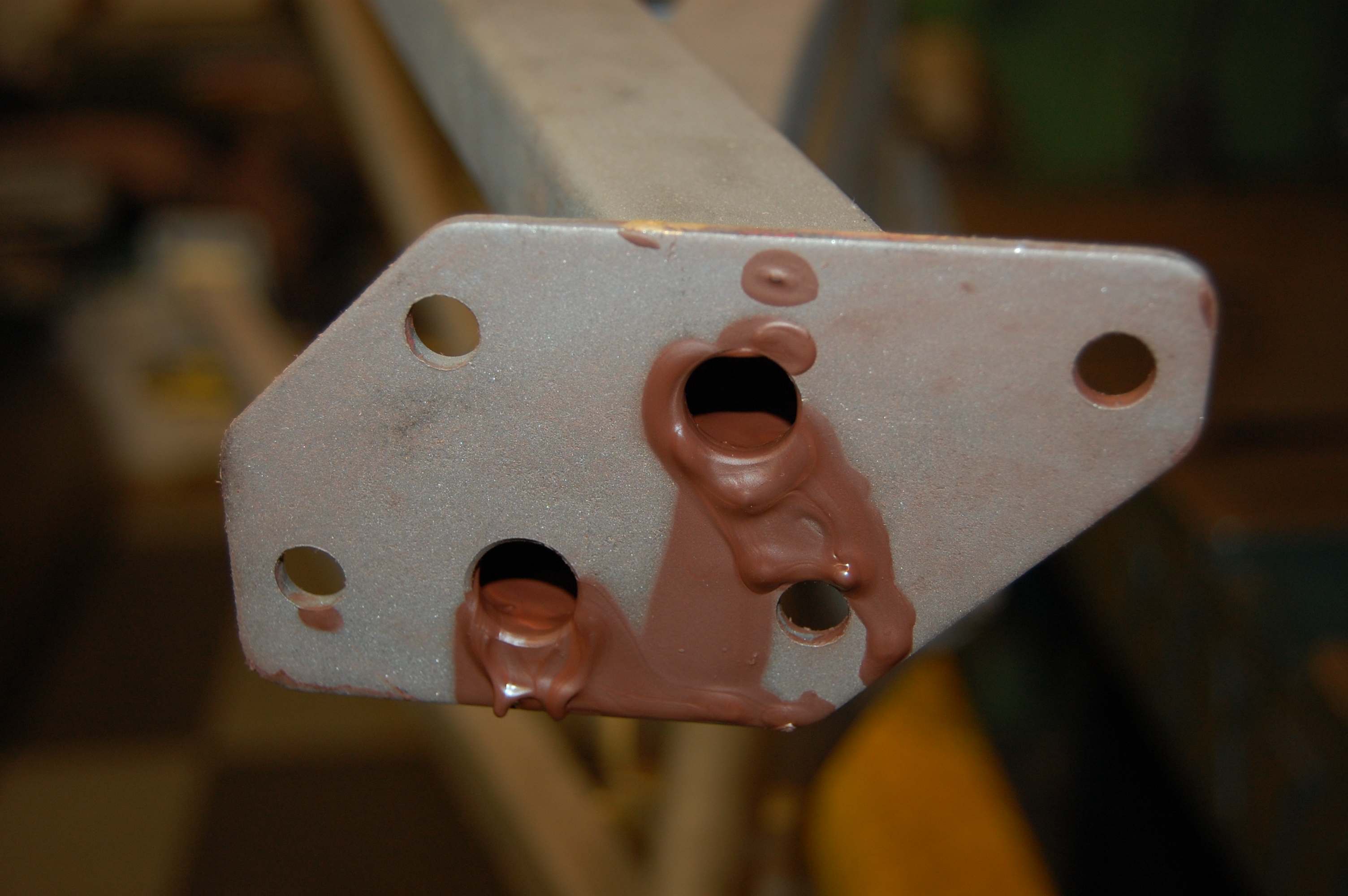

Here are those rails 48 hours later. These holes in the end are normally 5/16″ and I believe are there to relieve heat and pressure during the brazing process. We add some where ther are none, and use a step drill to get them as close to 1/2″ as possible. That allows you to get most of the flakes inside the rails out.

How to save your E-Type Frame Rails