This is the photo from the advertisement I ran across - the poster was looking for a used section to help here - I'm sure they never imagined I was busy at work across the Atlantic trying to form this exact piece...

In our ongoing efforts on reproducing all E-Type panels, one of the biggest challenges has been the firewall recesses. I have tried to get these right with mutiple machines and methods over the past few months, and I FINALLY succeeded on the fourth attempt! I won’t get into how much I spent on tooling to make this one simple panel below – or how it’s done – that’s top secret stuff…

Anyway, I ran across an ad on the internet from a gentleman in Ireland looking for a repair section for the firewall on his Series 1.5 2+2. Just like the ’66 FHC donor tub in our shop, his firewall had been cut to install an aftermarket AC unit – and I’ve seen this on other firewalls over the years as well. He was looking for a section of a used firewall, as E-Type firewalls and cowls have always been “the Holy Grail” – it’s the one thing you just can’t pick up the phone and order – until now…

The completed piece - I'm really proud of this one. E-Type firewalls have been unavailable throughout my entire life - not any more!

I formed this patch panel from new cold-rolled steel – it is EXACT in every dimension. It’s still in transit as of this writing, but I know he’ll be very pleased.

Looks even better upside-down for some reason... The recess is EXACT - it is the correct size, shape, depth, corner radius, and the shape of the slope down into the recess is also exact. I was actually running around the shop waving this in the air when it was finished!

Of course, to make it perfect, it needed the welded nuts for the throttle linkage brackets and the washer-bottle. These are the correct thread, although the shape of the outer portion of the nut is a little different (the square ones are easier to tack on when they are that small...) These are un-seen, so I did take that liberty...

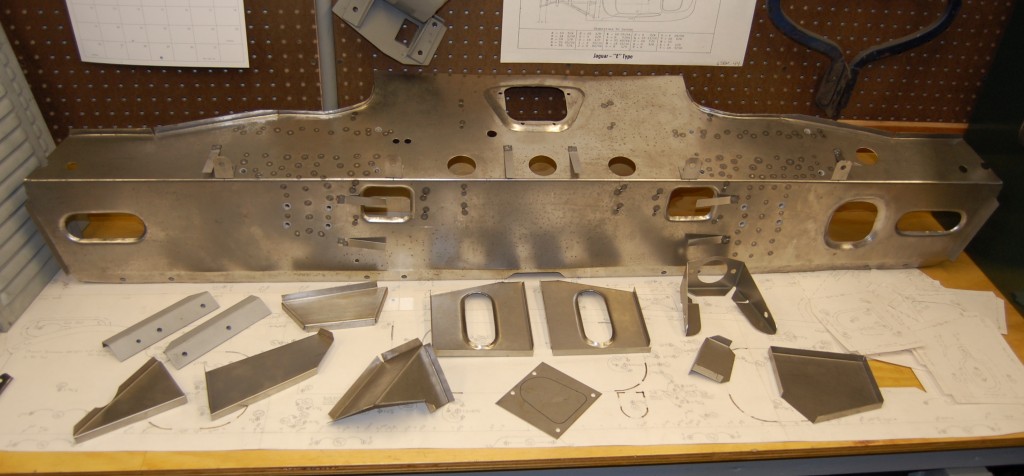

We've already formed the large backside of the cowl assembly, and most of the smaller internal gussets, etc. Now that the firewall recess problem is resolved, we'll soon have a full firewall formed and be able to assemble this all-new E-Type cowl assembly!

The panel finally arrived in Ireland, and here it is fitted up against the damaged firewall. I'm very pleased with the way this turned out - it's a dead match in all dimensions, although there did seem to be a slight depth difference with the recess on the other side of this car's firewall - the LH side was 1/16" deeper than this repair piece. The repair piece is IDENTICAL to the firewall it was patterned after, but after going around the shop, I can see that there is about that much fluctuation from car to car... Luckily, the way the tooling is designed, I can adjust this depth on future repair pieces to match the car being repaired.