And here is the Gold Medal performance…

OK – this is the one that had me screaming stuff like, “I’m the man!”, and “I am the MASTER OF METAL!” earlier today – through a respirator. Yes – Brent and Janie both have to put up with alot around here – and the intensity runs to both extremes – sometimes it’s more like, “This F*%*&%ing thing is really pissing me off!” – followed by flying tools…

But the past couple of days, and actually, the past few projects have gone REALLY well – I think I have hit a new level on the fabrication, and this project just really came out well and I’m proud of the work.

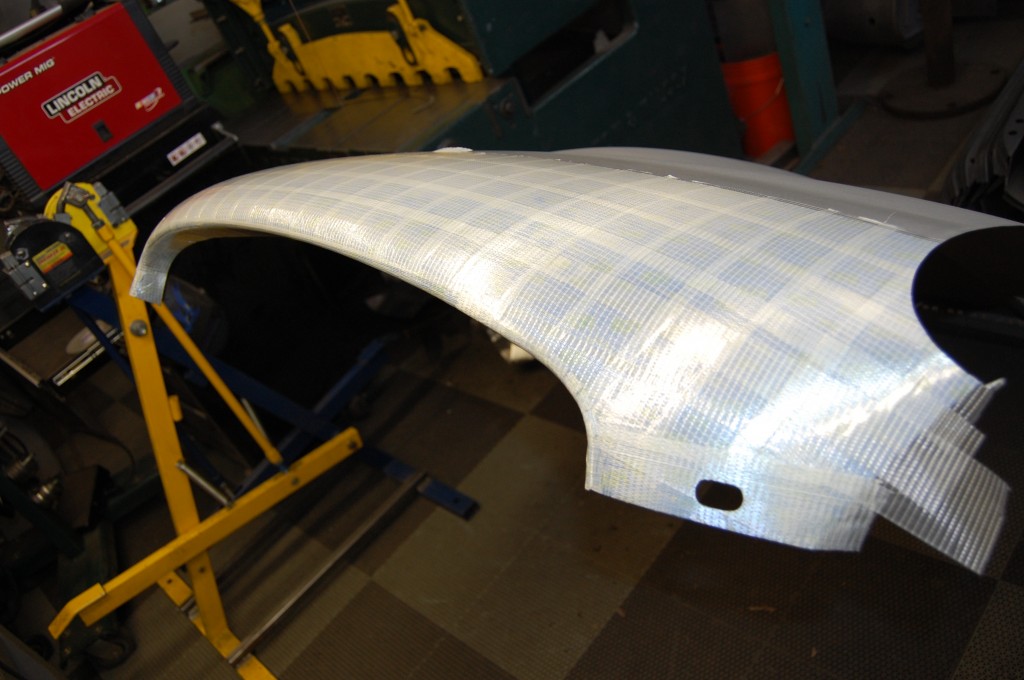

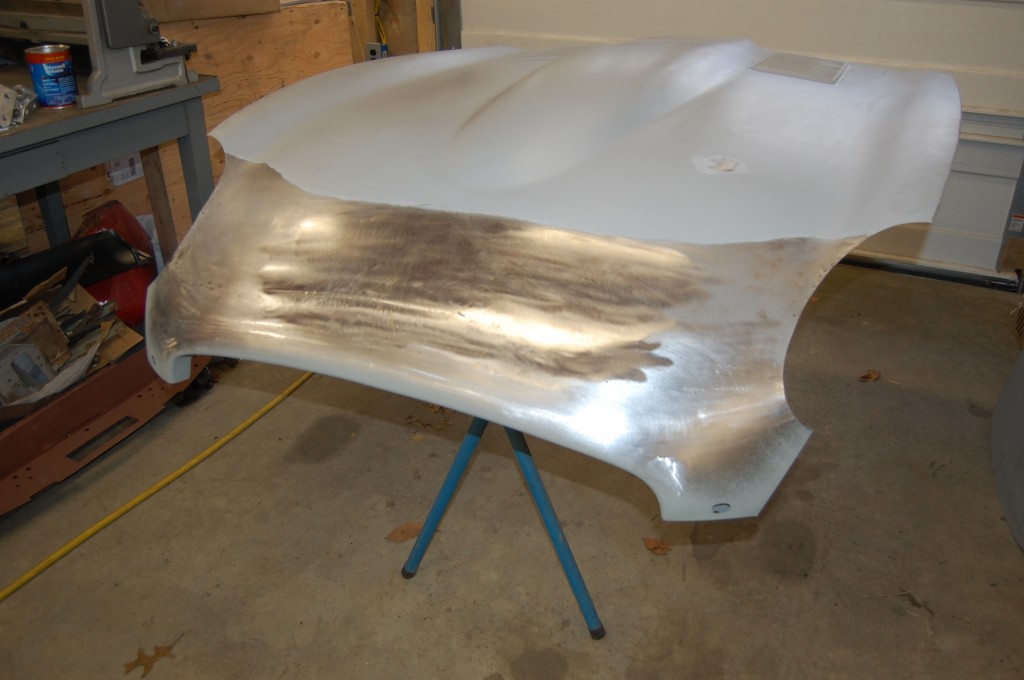

This is a Series 2 bonnet that came in last year. It had rust problems here and there, but the biggest issues were REALLY BAD repairs in the past after a collision that damaged the very front of the nose. The center section is absolutely flawless up until about the first 6 inches – but that area was just flat-out un-restorable. I was actually going to try it to some degree, but once we stripped the epoxy primer it was delivered in, and saw LOTS of brazing – that was the death blow…

I had completed the work on the flanges, all diaphragms and mudshields, and the inner valances last Summer, and then got sidetracked. Plus the owner wasn’t coming back until this year, so there was no rush. When I finally pulled out the wings and center section to finish them up, things were ALOT worse than I remembered.

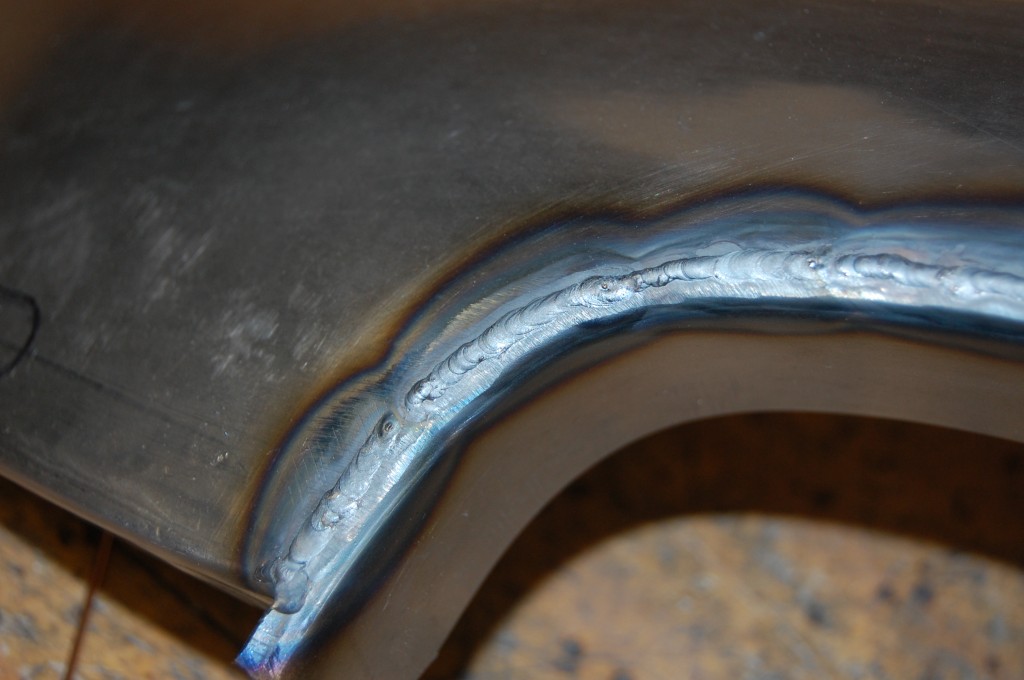

I repaired the LH wing first – it was messy in the front section, but not as bad as the RH. Well, it DID get me going – the metal was rusty and ground down and the small patch I was putting in kept blowing through where I TIG-ed it in – the metal was just so thin!

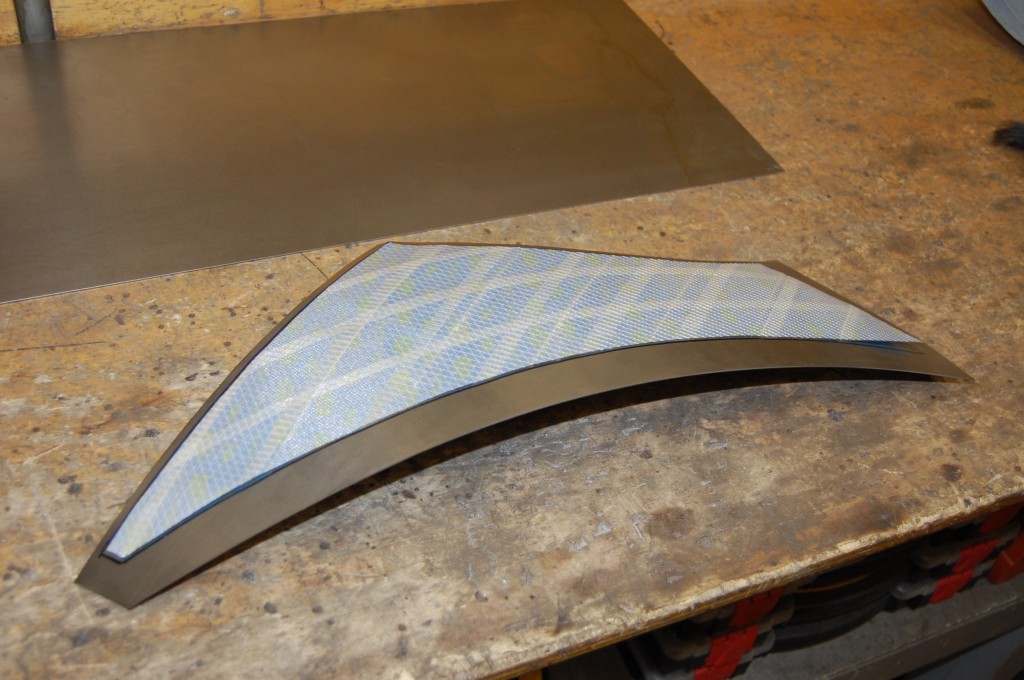

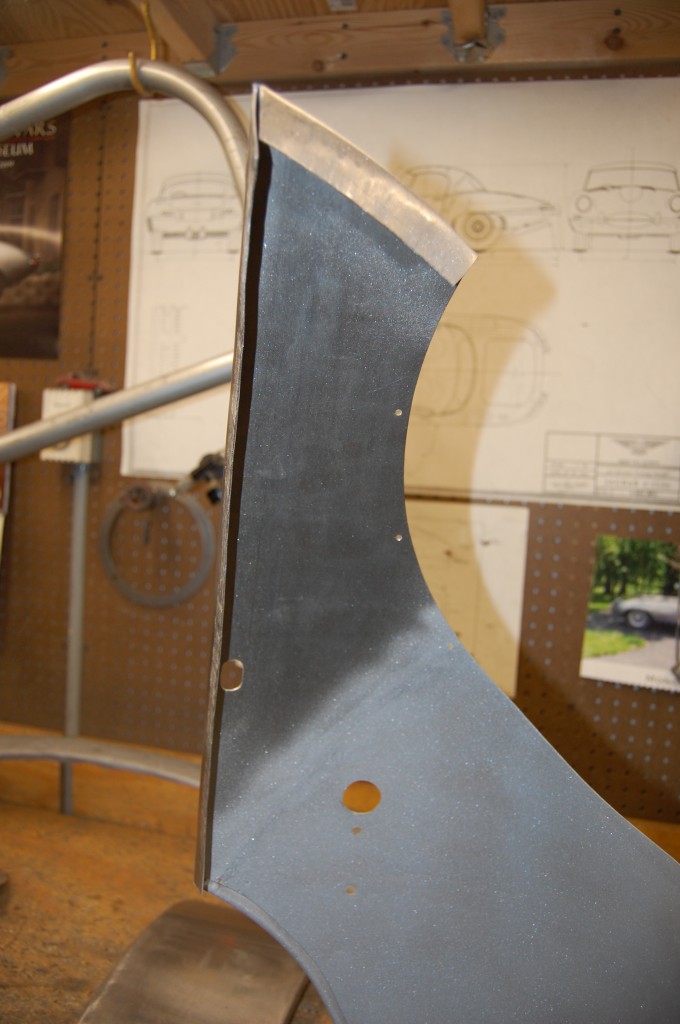

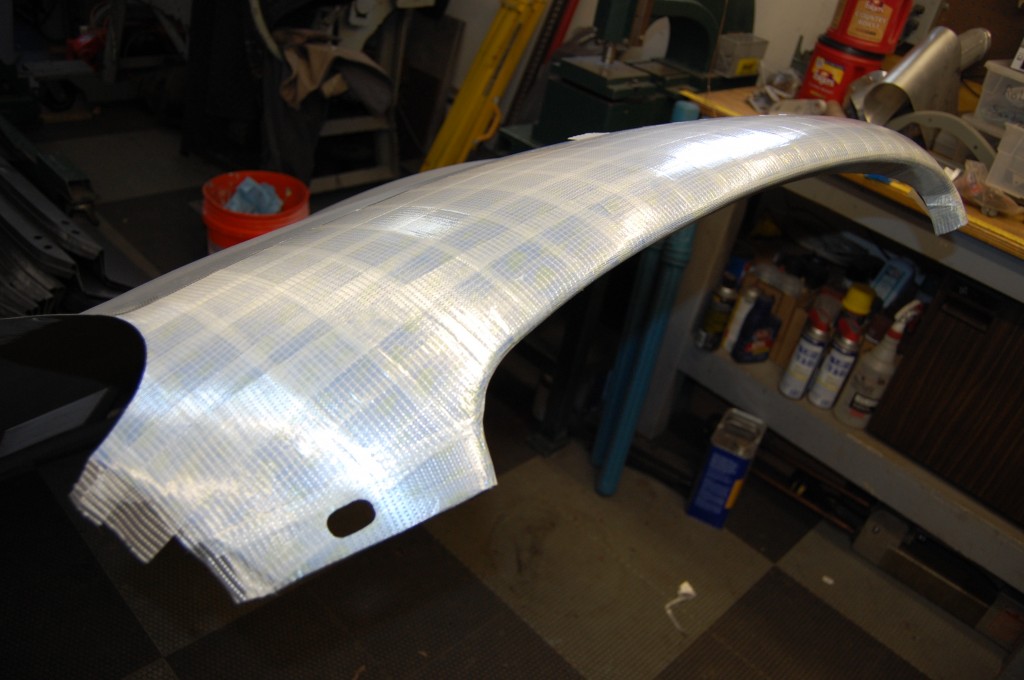

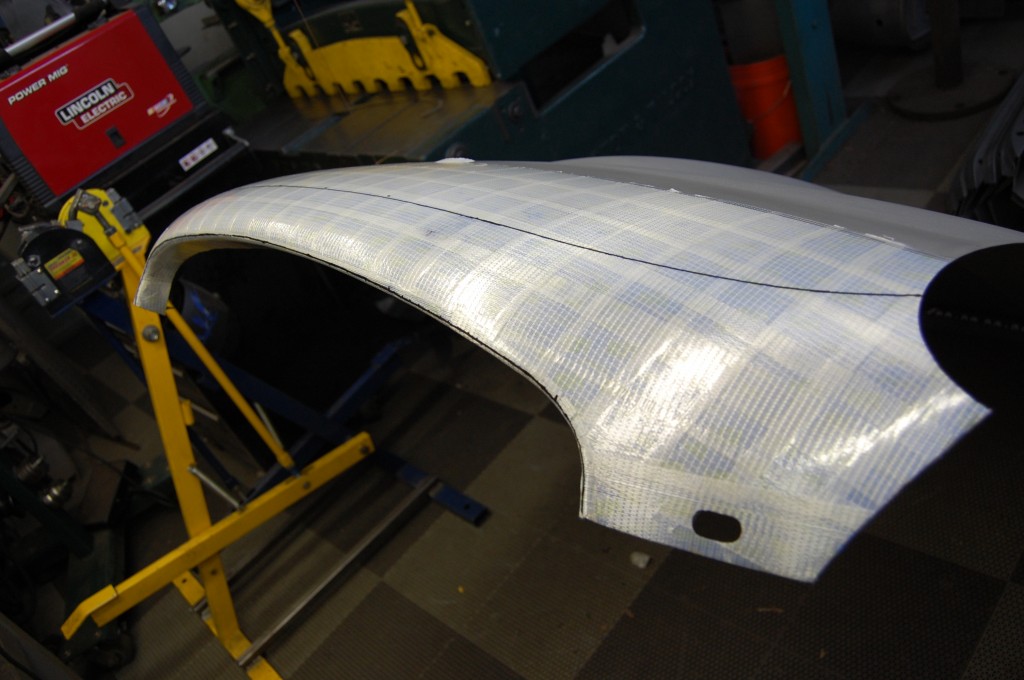

So the next day, I took a new approach on the RH wing, which was really just shot from the wheel arch forward. I decided to fabricate an entirely new section for up there, and that turned out GREAT!

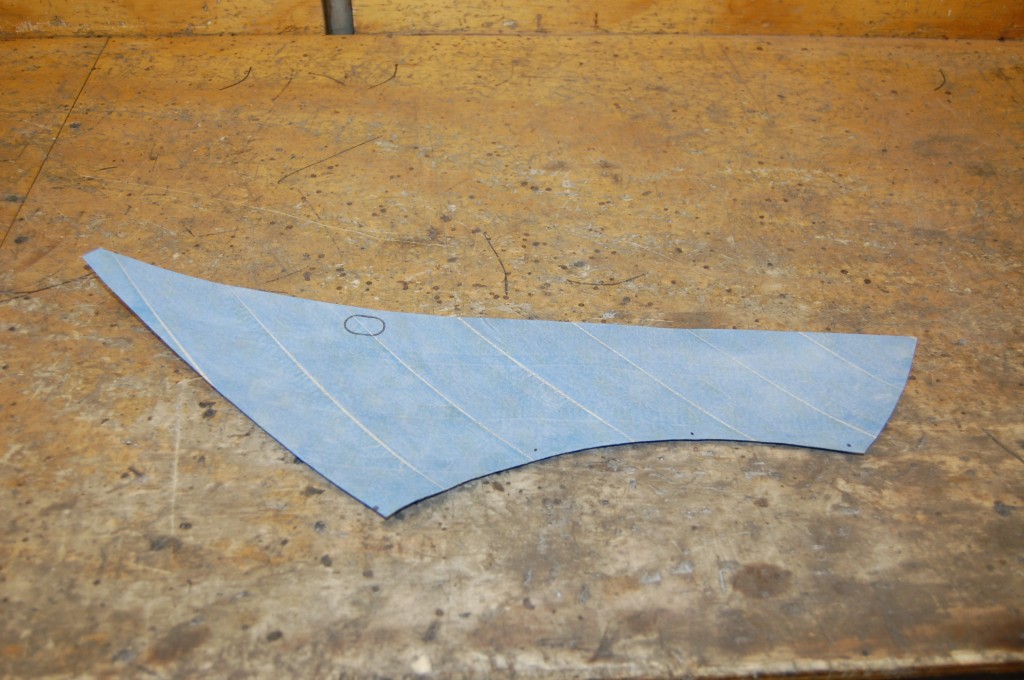

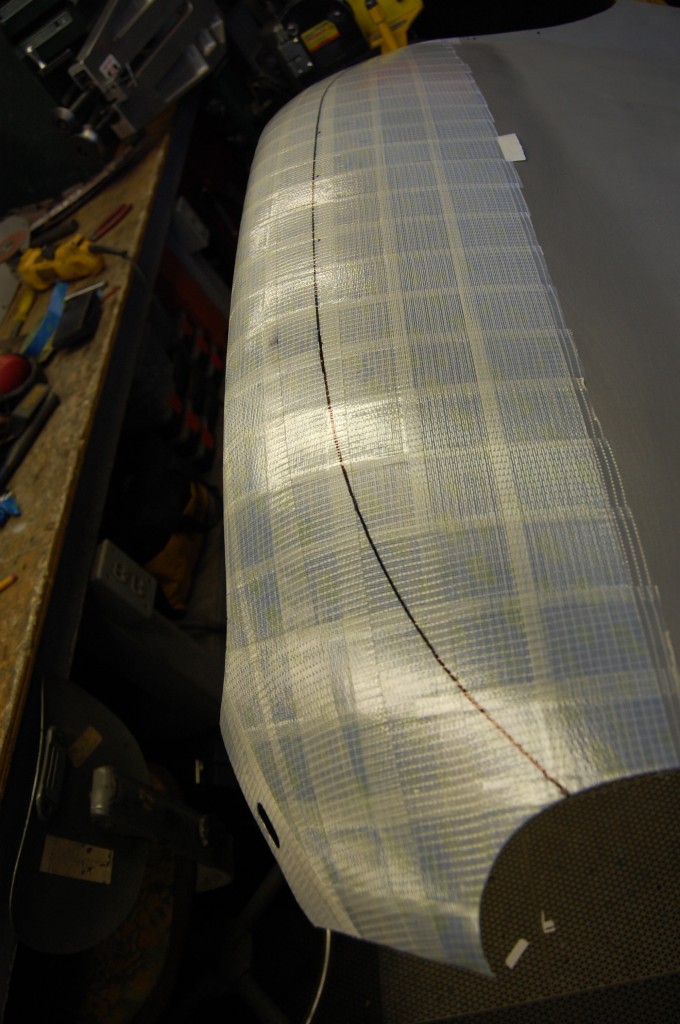

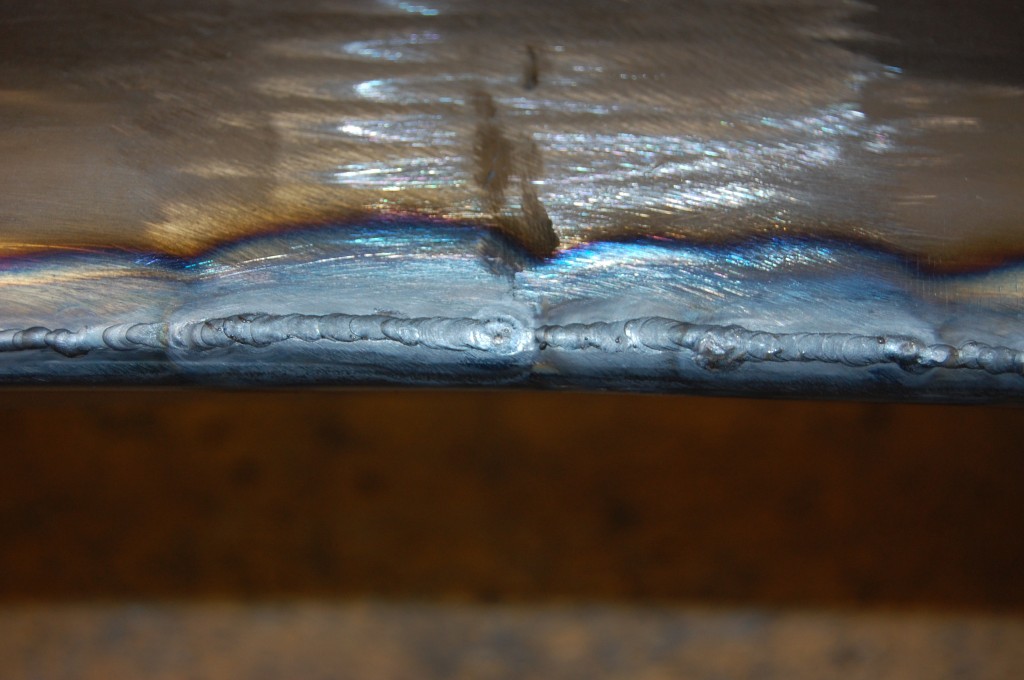

Well, then I of course was felling pretty strong, and decided to repair the center section with two good sized patches in the forward corners – I have done patches here before. But as I was patterning another excellent Series 2 center section and laying out where I would tie in the patches, I got gutsy and decided to try and make the whole nose in one complete piece and just replace it ALL!

Well, just like the Olympics, sometimes you choke, and sometimes you rise to the challenge. This was a one shot deal – the customer is coming on Friday… And let me tell you – slicing the nose off that center section took some real guts!

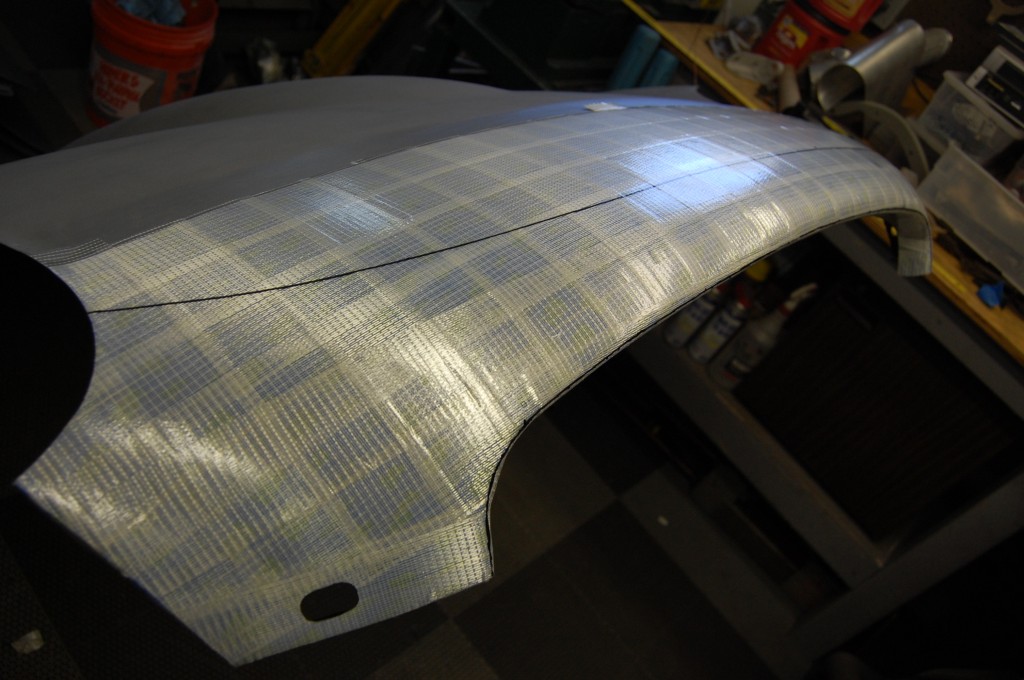

Needless to say, I didn’t choke – as a matter of fact, I think this was the metalworking performance of my life! In the last few photos, this center section is stacked on top of the original Series 2 that I used to make the pattern. Aside from the fact that I still have to put in the bumper holes, you can hardly tell the difference! And it feels as food as it looks!

P.S. Just so you don’t think I’m a total egomaniac, I promise that soon I’ll do a blog on something I REALLY screwed up – it’s not always perfect around here!