Both of these Series 1.5 open-headlamp bonnets were completely restored in our shop, and converted to Series 1, covered-headlamp configuration. Have a look through our blog postings at the right for THOUSANDS of photos of bonnets being properly restored at Monocoque Metalworks!

…AFTER Monocoque Metalworks!!! Same panel – I swear! Take a look at the restoration of this piece in our blogs!

The bonnet of an E-Type doesn’t do anything to hold the car together structurally, but it is THE key focal point of the car. Plus, it also accounts for nearly half of the external bodywork! It needs to be restored properly – and present itself as well from the underside as the outer surface, and Monocoque Metalworks can help get YOUR E-Type’s bonnet back into that condition!

Unfortunately, an E-Type’s bonnet is also extremely exposed, and vulnerable to crash damage from overly excited pilots, AND other drivers who don’t see the low frontal area in parking lots, etc. It’s VERY RARE for us to see a completely undamaged bonnet come in – they have almost all been at least “tapped” at some point in their past. We see everything from the typical nose dings and creases from the front bumpers getting tapped, all the way up to major wrecks that have been poorly hammered out in the past and filled with up to ¾” of plastic filler! Rust can also take a heavy toll on the bonnet, and we can erase that damage as well.

In addition, there is a current worldwide shortage of bonnets – they are not currently being produced by the “usual supplier”. A new supplier has arrived on the scene, and while I know very little about these panels, the stories I have heard are all the same – poorly fitting panels that scream reproduction… Read on to learn how we can restore your original bonnet perfectly, or replace it with another expertly restored original.

The new bonnets – when available, have poor build quaility, lots of bare metal between panels, incorrect hardware, and several features that scream reproduction. On top of that, they don’t fit worth a damn… I always prefer a properly restored bonnet built from original components, and you should too! We have a large stock of restorable original bonnet panels – these are just SOME of the center sections and wings – there are ALOT MORE in the warehouse! We have the pieces you need to get your bonnet back into shape – any year, any Series!

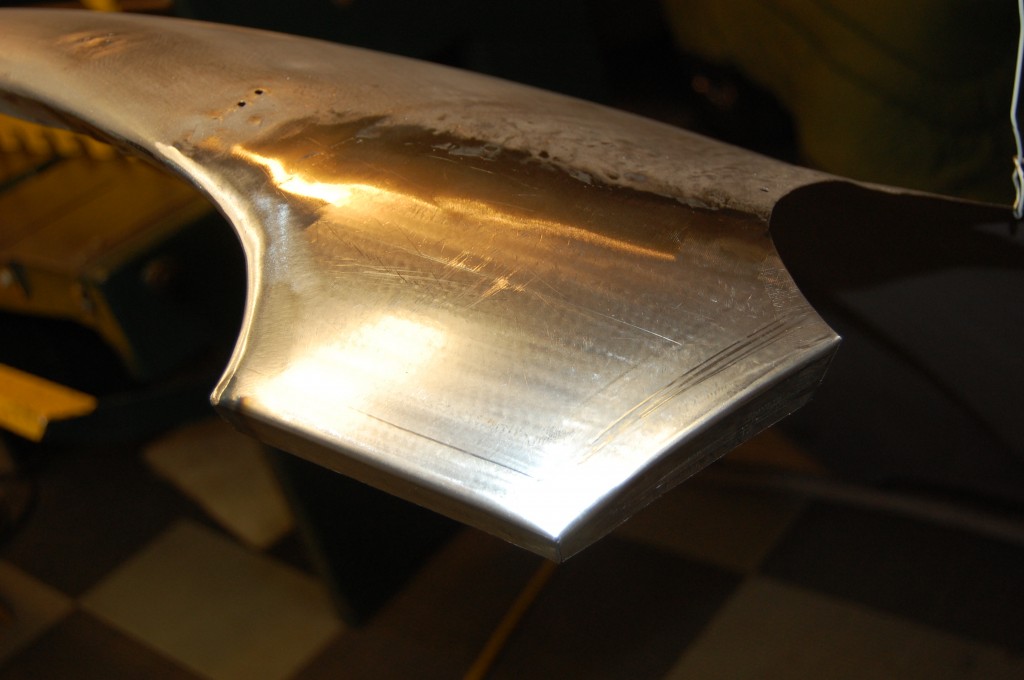

Expert Reshaping of Crash Damage – Whatever condition your bonnet is in, we can make it NEW again! We use a combination of hand hammering and machines specifically tooled for E-Types to perfectly reshape your panels to the factory specs – ensuring that the all important air intake, or “mouth” is the correct shape – something that in itself will make or break an E-Type restoration… The bonnets that leave our shop in primer look like they have already been filled at first glance, yet there’s nothing there except properly shaped steel and etch primer.

Same Bonnet – after LOTS of hammer and dolly and other metalwork! This is one coat of wet self-etching primer over bare metal – if you don’t believe that – look through our “E-Type Component Restoration” blog category, where you can read the full story of this bonnet being repaired, with dozens of photos taken along every step of the way. There is literally no bonnet we cannot repair!

Rust Damage in the Center-to-Wing Flanges – E-Type bonnets were assembled at the factory in a light coating of primer (if that), and then sprayed once assembled. In addition, the center-to-wing flanges are bolted together with a thick spacer washer to allow clearance for the brass, chrome molding clips to fit down through. These two facts resulted in an almost bare metal seam, 1-inch deep and 1/8” wide that is directly above the front wheels, trapping road grime, salt, and moisture. It ALWAYS rusts, the question is how far has it gotten… It can be a light surface coating if you are lucky that we clean back down to white metal, but it can also be rotted out in this flange, and in the worst case, can work its way up over the fold and start rotting holes into the other skin. We currently are the only source – worldwide – for new center-to-wing flanges, and we can TIG-weld these in to save your center section and wings, replacing larger sections of the curved outer skin as well if necessary…

We have made sucessful repairs here MANY, MANY times – and have the tools and required welding skills to do it right, without warping the wing itself. This will be ground down and trimmed, aligned with factory-correct templates to reset the curvature, and then the holes will be re-drilled. When completed, it will be new again – inside and out!

Rotted or Twisted Bonded Flanges – Most of the outer skin of an E-Type’s bonnet is bonded (or glued) to metal flanges that are bolted to the inner bonnet panels. These flanges were also poorly primed and painted, and they rust badly where they meet the inner bonnet panels, quickly ruining the flange. While these are simple pieces overall, their curves must be exact for proper bonding. These pieces have been unavailable new for the E-Type’s entire life – until we started reproducing them in our fabrication shop last year, that is! We can now ensure that every single flange on the bonnet is rock-solid and properly shaped.

Fabrication and Replacement of the Main Support Member – We call this piece “ground zero for all bonnet alignment” – it contains the mounting points for the bonnet hinges and support springs, and supports the entire bonnet. It MUST be rock-solid and straight, but unfortunately, is it rarely either… Previously, the only solution here was to purchase a new lower valance at a cost of $1400 or more, and as a reproduction, it rarely fits the center section and wings without considerable adjustment. We now manufacture this support piece, and seamlessly attach it to your existing lower valance’s outer skin.

In this photo, one of our new bonnet support members has been used to restore this Series 1 Lower Valance.

Other Cancerous Rust Areas – The other areas that commonly rust on an E-Type’s bonnet include the outer skin above the bonded flanges, the rear support member (from the inside, out…), and the spot-welded seams that attach the air duct to the mail wall of the inner valances. These are all areas we have experience with repairing – don’t let any of this damage convince you that your bonnet is “unrestorable” until you talk to us!

Not so much a rusted area, but this corner of an otherwise very nice Series 2 center section had to go…

Here is our solution – NO filler required! Follow the step-by-step restoration of this bonnet in our blog posts. You’ll see literally THOUSANDS of metalwork photos of the MANY bonnets we have restored here at Monocoque Metalworks!

Extreme Care in the Stripping Phase – Sandblasting, Media Blasting, Soda Blasting, Chemicals, Dipping, Heat Guns, Sanding, Razor Blades – over the past 25 years, I’ve explored every possible method that can be used to strip panels, and have learned what does and does not work. Most importantly, we know what can damage a panel, and we know which methods to employ to strip your panels correctly. We have seen bonnets severely gouged by DA sanders with coarse grit discs, and severely warped by powerful sandblasters more appropriate for stripping locomotives… DO NOT entrust your center section to anyone who does not share our fear of damage to the panels in the stripping process! Saving a few dollars in this phase can damage your bonnet beyond repair – nothing is worse than the damage caused by overly-aggressive stripping! We will strip your panels bare without damage – and almost always use multiple methods to get the job done right.

This is a Monocoque metalworks specialty – converting Series 1.5 open-headlamp bonnets to Series 1 covered-headlamp configuration – seamlessly. See our blog entries that document this process step-by-step.

Precision Assembly – Re-assembling an E-Type bonnet can be a real test of patience for the professional, and can quickly reduce an amateur to tears – I’ll admit it – I’ve been that guy… What usually happens is that the assembler eventually gives up on getting it right, and just settles for getting it together any way they can. That doesn’t happen here – we know how to do it correctly and we’ve done it many times. We know what to check, what to look out for, and have our own little tricks to do it right. When panels are being replaced, they can be adjusted – correctly – in our fabrication shop. In the end, this saves you money, because we’ll spend half the time doing it right that another shop will spend doing it wrong!

Attention to detail in the assembly phase is crucial! Every bonnet that leaves our shop looks like this – everything properly aligned, bonded flanges that are clean and uniform, correct, new hardware (or restored originals at the customers request), and guaranteed to be suitable for a 100-point restoration!

Early Bonnets a Specialty! – the first car I restored professionally was an early ’61 Roadster, which still had its complete original bonnet. While most restorers realize that early cars should have spot-welded louvers, they are unfamiliar with the MANY other nuances of an early E-Type’s bonnet. The flanges are also spot-welded to the outer skin, much wider, and shaped somewhat differently. When we restore an early bonnet, we reproduce all of these details EXACTLY, using two local cars (the same ’61 roadster and another coupe), both with their original bonnets – as our guide.

This is a welded-louver, welded-flange bonnet being handbuilt. These flanges were patterned after an original early 1961 bonnet – they are EXACT! When completed, this bonnet was a perfect early bonnet – William Lyons himself would have sworn it was original!

BONNET EXCHANGE! – All bonnets in our shop are rebuilt to the same exacting standards, and when available, we restore original panels we have on the shelf and combine them with new inner panels and flanges to produce beautifully restored, original bonnets. These bonnets are carefully assembled with restored original hardware, and all flanges are bonded with the correct adhesive. We use the machinery in our fabrication shop to match the flanges to the outer skin perfectly, resulting in a very even bonded seam on every flange. These bonnets are supplied completely etch-primed, inside and out, making sure that every inner flange surface and areas that can’t be painted once assembled have at least two coats of a high-quality, professional etch primer. These complete bonnets are sold on an exchange basis, pricing based on the condition of the bonnet you can supply as a core.

NEW LIGHTWEIGHT BONNET OPTIONS! – as a result of years spent supporting an E-Type vintage race team in my youth, the continuous search for lightweight components has gotten into my blood – if you’ve also been bitten by this, you’ll know just what I’m talking about, and be eager to read on to learn what we can do to shave weight from your E-Type!

Aluminum – we can reproduce the entire inner structure of the E-Type’s bonnet in aluminum, versus the original steel components. This includes the right and left inner valances, or “air ducts”, headlight diaphragms, “sugar scoops”, mudshields, and flanges – even the main support member including the caged hinge mounts. We can also modify these components – removing the factory air ducts and re-routing them as brake cooling scoops, for example. We are not yet able to supply the outer skin itself in aluminum, but we are working on it!

We are slowly but steadily moving toward aluminum bonnet and shell construction. Our latest challenge is the restoration of these aluminum race bonnets from a well-known E-Type racing team. These bonnets had a tough 2012 season, but we’ll have them restored as good as new soon, ready for more abuse in 2013!

UPDATE! – Here is the #61 Donovan ALUMINUM E-Type bonnet after restoration in our shop – actually, MULTIPLE restorations by us, as so goes the nature of vintage racing… This is one of two factory original aluminum racing bonnets produced by Jaguar in the 60’s without headlamps. After several seasons, we have now hand-fabricated almost every square-inch of this bonnet to patterns pulled from the original wrecked factory bonnet – though a portion of the original center section that includes the power bulge does remain. In this photo, it has been returned to their shop, and awaits re-fitting to the body shell in the background.