Well, we’re forging ahead, but the clock is also ticking!

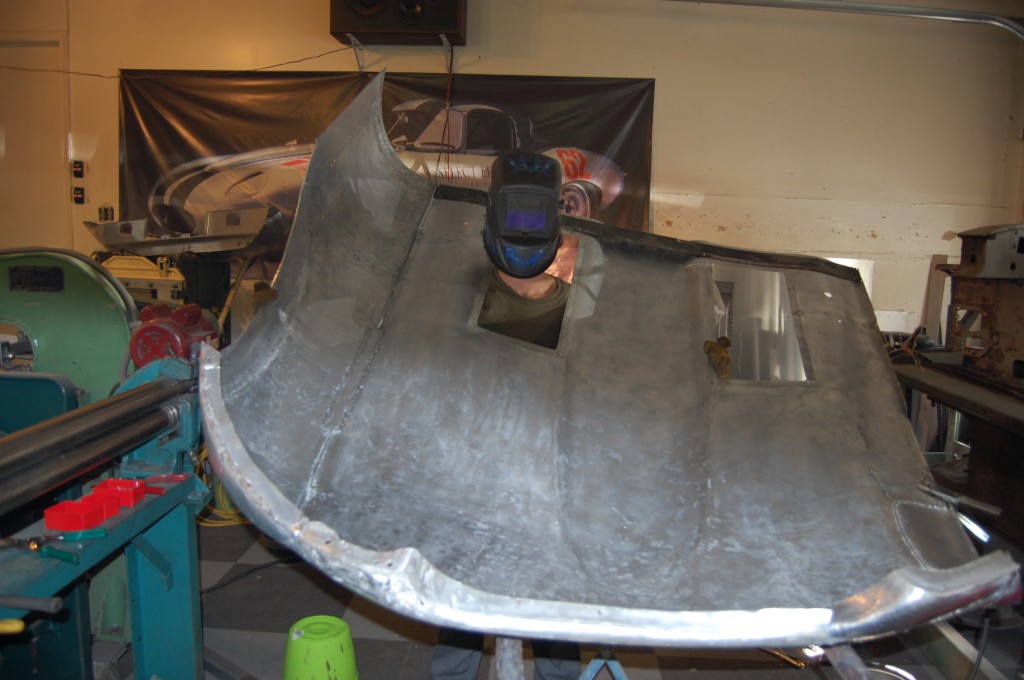

Yesterday, I turned my attention to the carnage in the lower RH corner of the mouth opening. I’ve basically just been ignoring this while there were bigger issues to tackle, but as of yesterday AM, this was now the biggest issue. Making a patch for this turned out to be tough because the problems were over a relatively widespread area. It hurt to start cutting away at the center section again after it looked so good finally with that side patch, but I had some coffee and dove right in!

I was trying to do a little demo on taking a piece of flat aluminum and turning into this complicated shape, but my first attempt had too much curve, and I went to a second piece – which I ended up screwing up, cutting off, and spinning upside down and doing that way… I had this plan of writing my name on it and having that on there after it was completed, and that kind of worked, but after about and hour and when things got complicated, the “demo” thing was out the window and I was just working…

In the morning yesterday, I bolted everything together and it was a little “wracked”, but it looks like I can take that out when I assemble things – which I can actually do now with bolts vs. vice grips since alot of flange repairs have been made.

Today, I’ll be finishing off the mouth corner shaping the whole mouth – that is why it is not completely welded in there. Then planishing, smoothing, and shaping the whole RH side of the center section. Wish me luck! – Chuck